6 Back cover assembly

6.1 Tray feeding mechanism

Back covers, due to their sensitive cosmetic components, are packed into specially designed trays. To accommodate such packaging, the feeder is made of an input conveyor, stack separator, single-track transport system, tray stacking mechanism, and output conveyor. The system is specifically designed to accommodate trays with dimensions up to 400mm in width and 600mm in length. To enhance the machine's operational autonomy, the conveyors at both the entry and exit points can be extended, provided that space constraints permit.

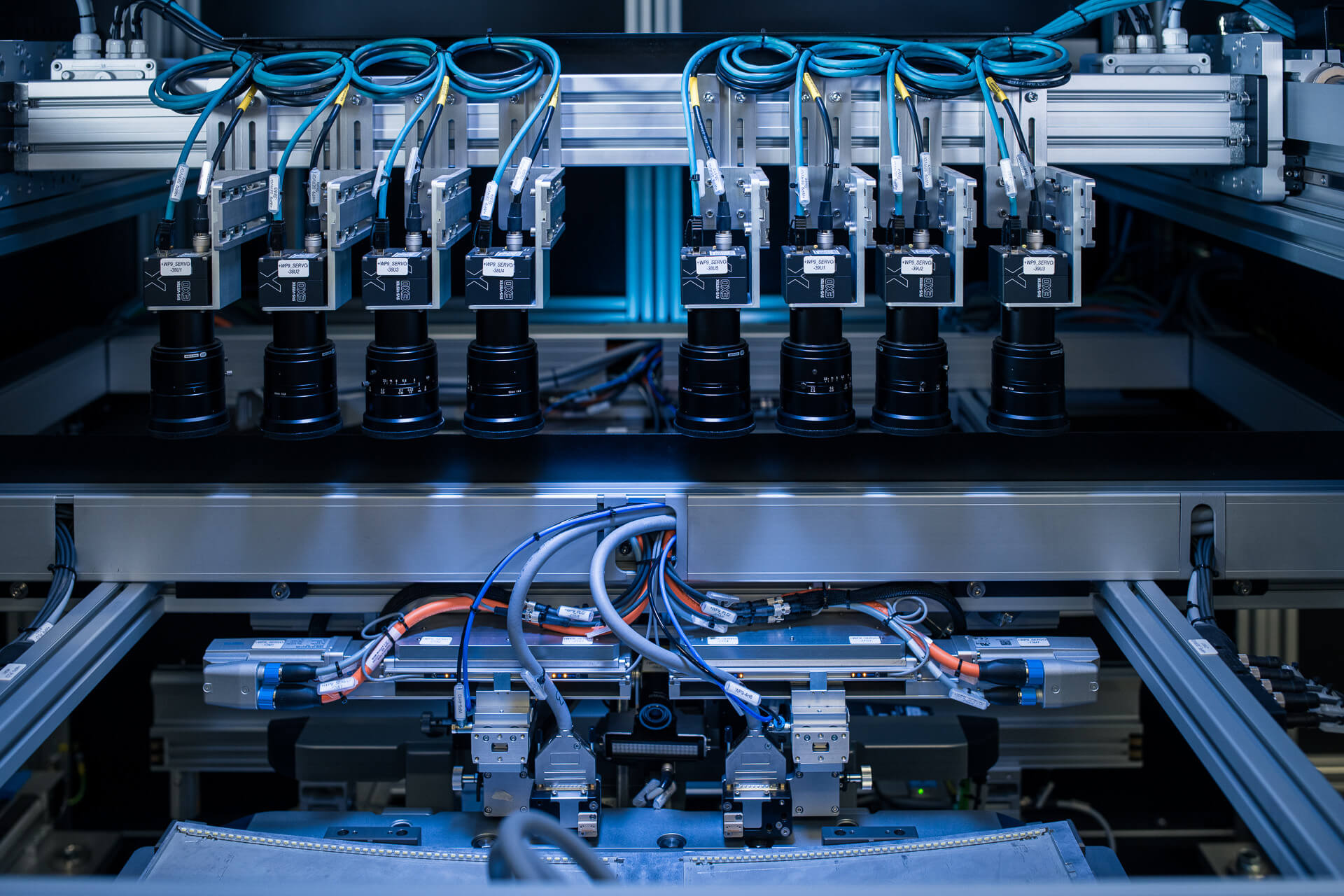

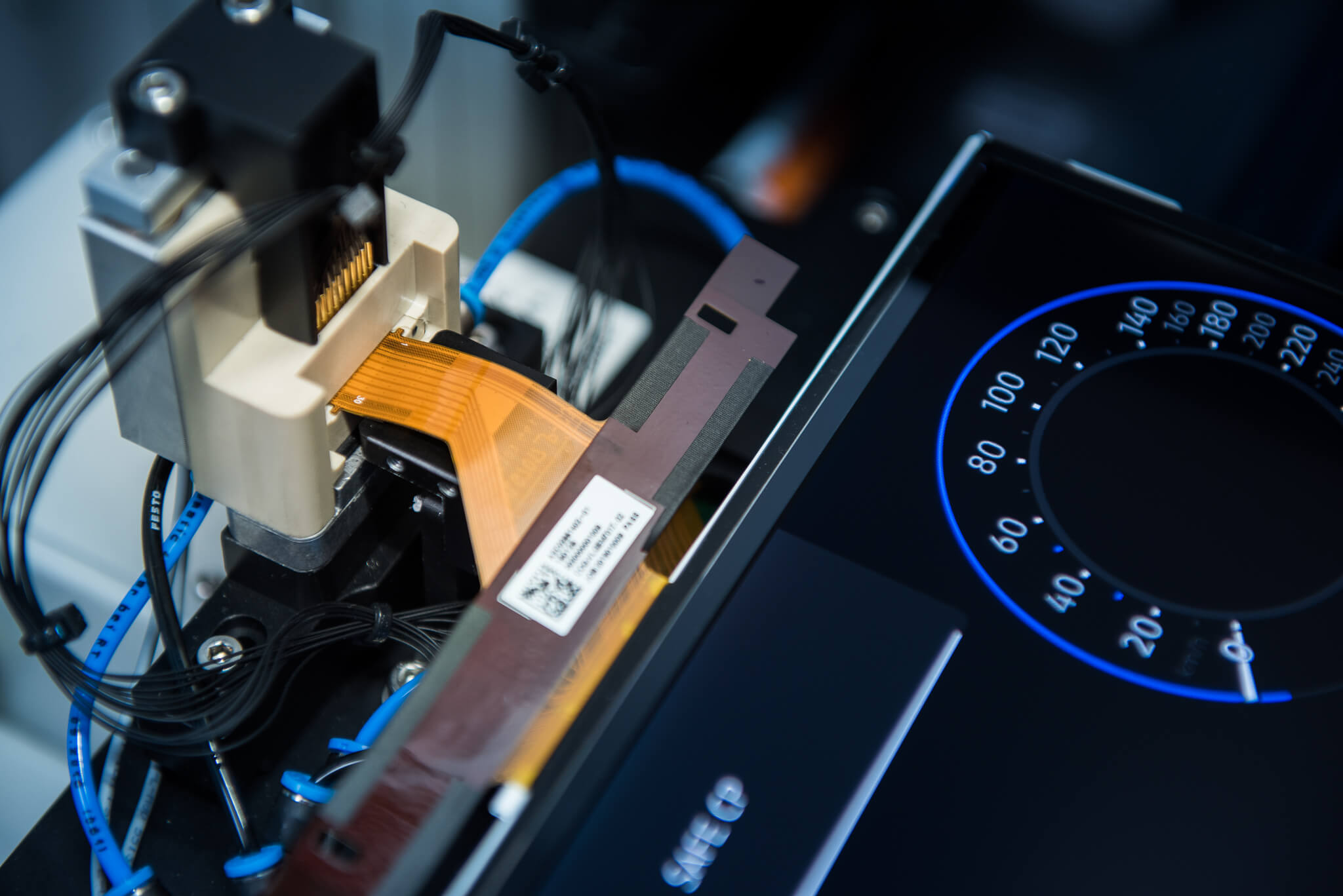

The mechanism's critical components are the stack separator and tray stacker, which are custom-built to be adaptable to trays of varying dimensions and material compositions. To facilitate accurate tray separation, servo systems equipped with purpose-built clamping mechanisms are used. A state-of-the-art vision system is deployed to pinpoint the product's spatial orientation and position, achieving a picking accuracy of under 0.1 mm. If the feeding tray's limitations do not allow for precise enough measuremebt, an additional pick-and-place system is used on a backlit table to improve visibility.

Overall, the tray feeding mechanism is an efficient and reliable way to automate the feeding of various components to the assembly process, reducing the need for manual labor and improving production efficiency.