Deployment date: September, 2023

The dual-screen single-panel instrument cluster and infotainment was designed by a premium automotive manufacturer for their newest line of state-of-the-art electric cars. One housing with two backlight panels illuminates two separate screens which span 750 mm in both left-hand and right-hand drive variants for global markets.

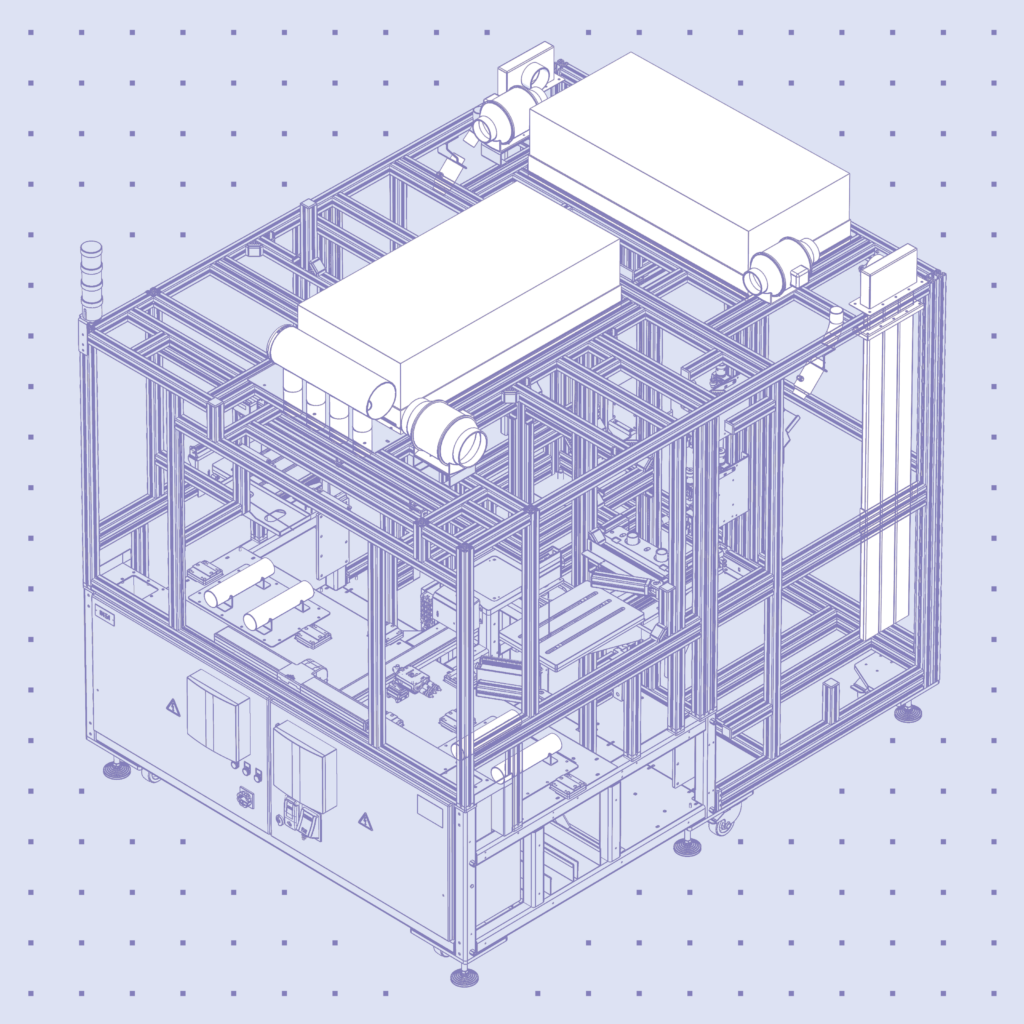

This backlight assembly line is almost fully automatic and integrates both backlight assembly and testing into one easy to maintain production line. The modular transport design and ISO class 7 clean room emulation features allow the line to be placed in a regular ISO class 8 electronics production environment with no impact to productivity or quality of the final product.

Industry:

Globally oriented Tier 1 automotive supplier for leading brands such as BMW, Daimler, and Volkswagen.

Product portfolio:

Primarily focusing on automotive interior electronics, complemented by a range of products like brake systems, safety systems, and powertrain components.

Location:

New European manufacturing plant

(one of 500+ globally)

99% FPY

New Product Launch Manager

Automotive TechnologiesI’d like to highlight the impressive support and response time from the INEA team throughout and after the project. We had a smooth ramp-up and kept standards high the whole time, so I'm sure that even if we run into problems, they will get resolved as soon as they possibly can.

To build an automated assembly line for assembling 26 different parts into a backlight unit for a 750 mm wide curved screen. Since backlight assembly requires low particle contamination in the air and the line was placed in a regular ISO class 8 assembly hall, the cells individually had to meet ISO class 7 cleanroom standards.

The line had to be versatile enough to switch between left-hand and right-hand drive vehicle variants quickly. This required a design that allowed for fast changeovers without sacrificing efficiency.

The project had a tight 12-month deadline with an additional 8 weeks for process validation. This tight schedule left little room for delays and made efficient planning crucial.

The assembly line integrates fan filter units with HEPA filters to emulate an environment that meets ISO class 7 cleanroom standards even when the line is placed on a regular factory floor. This is critical for minimizing particle contamination during the high-precision assembly process.

The line is designed to be efficiently managed from a single operator station due to full part traceability and MES integration. This station allows streamlined handling of all command inputs, messages, and warnings for the entire line, making the operation more efficient.

The line is engineered to allow a 15-minute changeover between left-hand and right-hand drive products due to the particularities of an assembly made of two differently sized displays for different purposes to the driver. This allows the production to adapt to market demand quickly and efficiently.

The assembly line is a comprehensive system with a layout size of 18 by 9 metres, featuring 14 machines. This includes one manual station dedicated to base part placement and the handling of the final product. The line is designed to operate under stringent conditions, emulating a clean room of ISO class 7 within the assembly and testing areas. It is expected to produce over 5 million products in its lifetime.

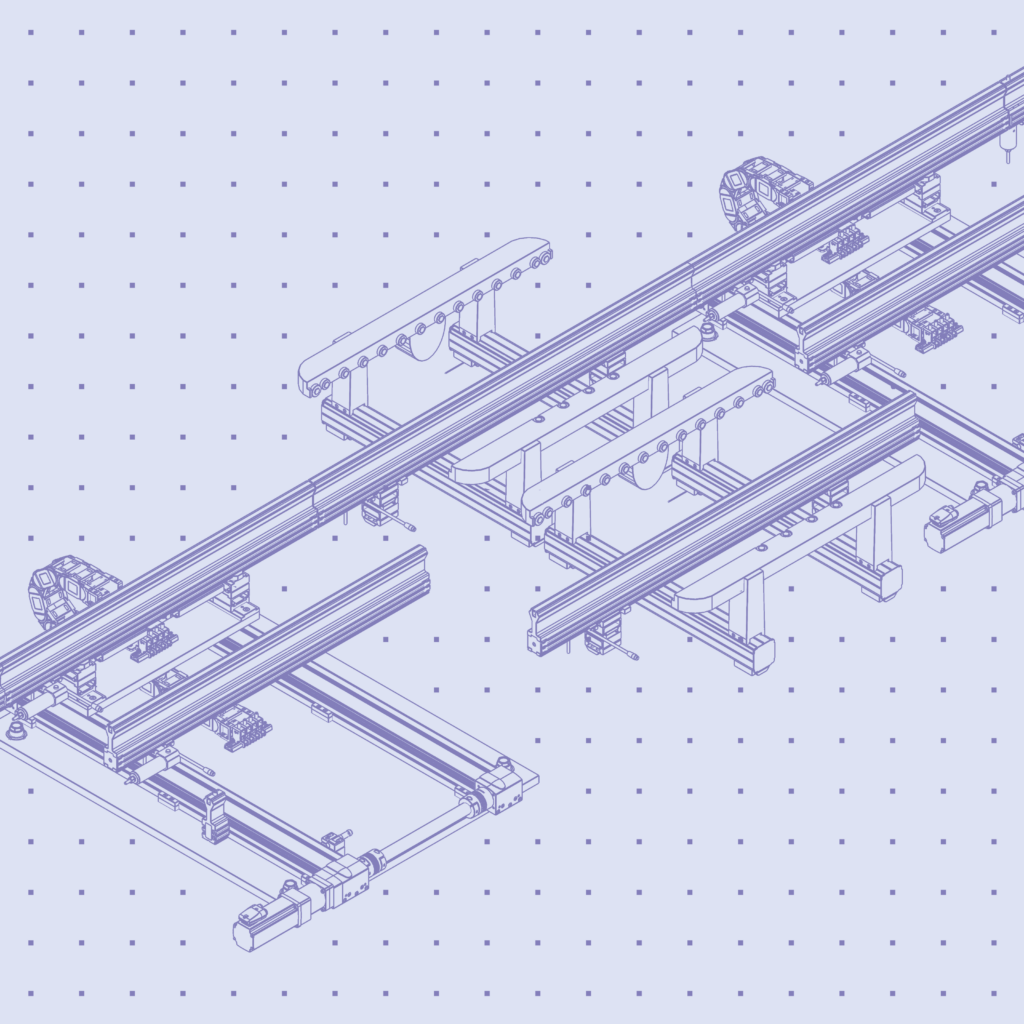

Parts are systematically fed into the line. Robots equipped with specialized vision systems are responsible for picking up these parts for assembly. These robots make use of specialised grippers and vision systems, specifically developed to handle the unique curved parts that are part of the backlight unit. The foil feeders, for example, include an ionized air blaster for no-contact separation and the curved grippers are made of a material which leaves no marks on the handled part.

The operation of the line is highly efficient, requiring only one operator who is responsible for the placement of the base part and the handling of the final product. The entire line can be monitored and controlled from one operator station as well. Regardless, the line was built for easy access from both sides for tool changeover and maintenance. It is capable of producing and testing two product variants—for left-hand and right-hand drive vehicles—with a changeover time of less than 15 minutes.

The line includes RFID tracking across the complete line and complete MES integration, providing an additional layer of quality control and traceability. The system logs each component’s path along the line, allowing for real-time monitoring and historical data analysis from a single operator station.

Additionally, the line’s design allows for energy consumption measurements for both air and electricity, providing valuable data for optimizing operational efficiency. It is also designed to be adaptable for future products, ensuring its long-term viability.

The assembly line includes ISO class 7 cleanroom emulation to adhere to the high-quality standards required for the backlight units. This means that the line can be placed even in an assembly hall which itself only reaches ISO class 8 standards, which requires no additional cleanroom construction. This cleanroom environment is maintained by fan filter units (FFU) that cover all workstations and the conveyor system. The FFUs are equipped with high-efficiency particulate air (HEPA) filters, which remove 99.97% of particles that have a size greater than or equal to 0.3 µm.

Each pallet entering the cleanroom is meticulously cleaned to maintain the integrity of the environment. The cleaning process involves multiple stages, including air jets and vacuum systems, to remove any particles that could compromise the cleanroom conditions. Each layer of protection has separately controlled air flow regulators that work together to keep the air below the needed particle contamination levels.

The assembly line features a specialized segmented transport system that allows for easy layout changes if that is ever needed. This system is designed for high precision, boasting a positioning accuracy of ± 0.03 mm. The transport system uses advanced servo motors and linear guides to achieve this level of accuracy, ensuring that each part is placed precisely where it needs to be for the next stage of assembly.

The transport system is autonomous and incorporates two transport lifters at the entrance of the line. These lifters are designed with an entrance height of 2 metres, facilitating easier access for part loading and unloading with an ergonomic box-case lifter. Even so, the line boasts an autonomy of one hour, meaning that manual material loading is needed very sparsely, allowing the operator to focus on monitoring and other specialised tasks.

The assembly line successfully automates a complex assembly procedure and only requires one human operator to run the entire process. Because of the state-of-the-art autonomous transport system and ISO 7 cleanroom emulation inside each cell, the product requires no special handling and the hall that the line is placed in requires no special air filtration, significantly reducing construction and operation costs. These features allow the customer to manufacture the products almost constantly, always able to quickly adapt to market demands for different drive side variations.

enabling line output of around 100 parts per hour

reduces downtime and makes better use of resources

almost entirely eliminates scrap and reduces the need for costly rework

on input material minimises the need for manual labour

Reach out for personalized service and expert guidance tailored to your unique needs. Our team is ready and eager to respond to any challenge.