with in-depth expertise and state-of-the-art technologies

to fully automate production, inspection, and testing.

Covering simple to complex shapes and rationalising

resource usage with operator- and maintenance-friendly design.

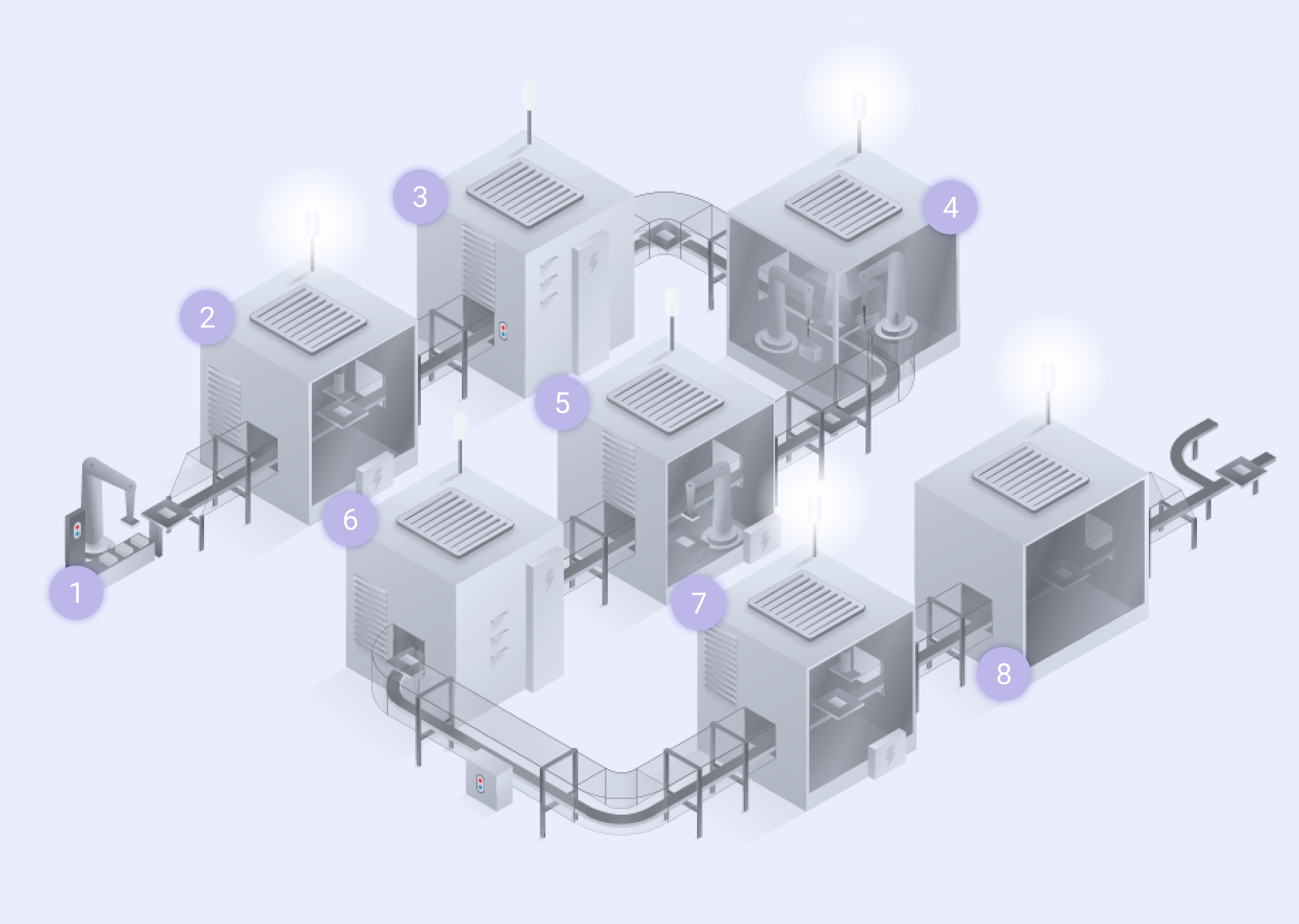

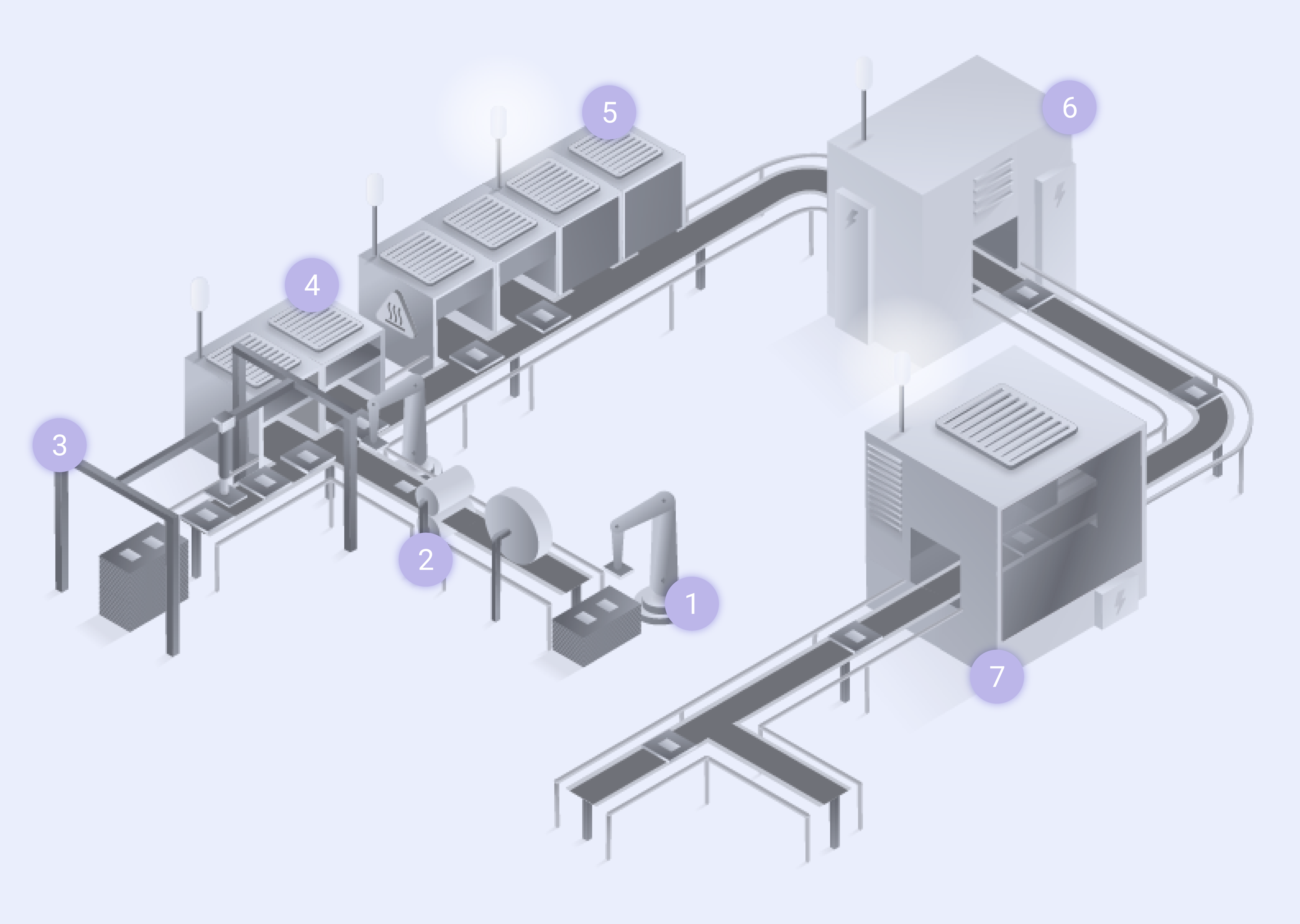

Completely automated assembly line and process optimization with energy saving capabilities and automatic feeding mechanism for long line autonomy.

Dry optical bonding of touch-sensitive displays of any curvature, shape, or type with soft-to-hard or hard-to-hard lamination for a permanent high-quality bond.

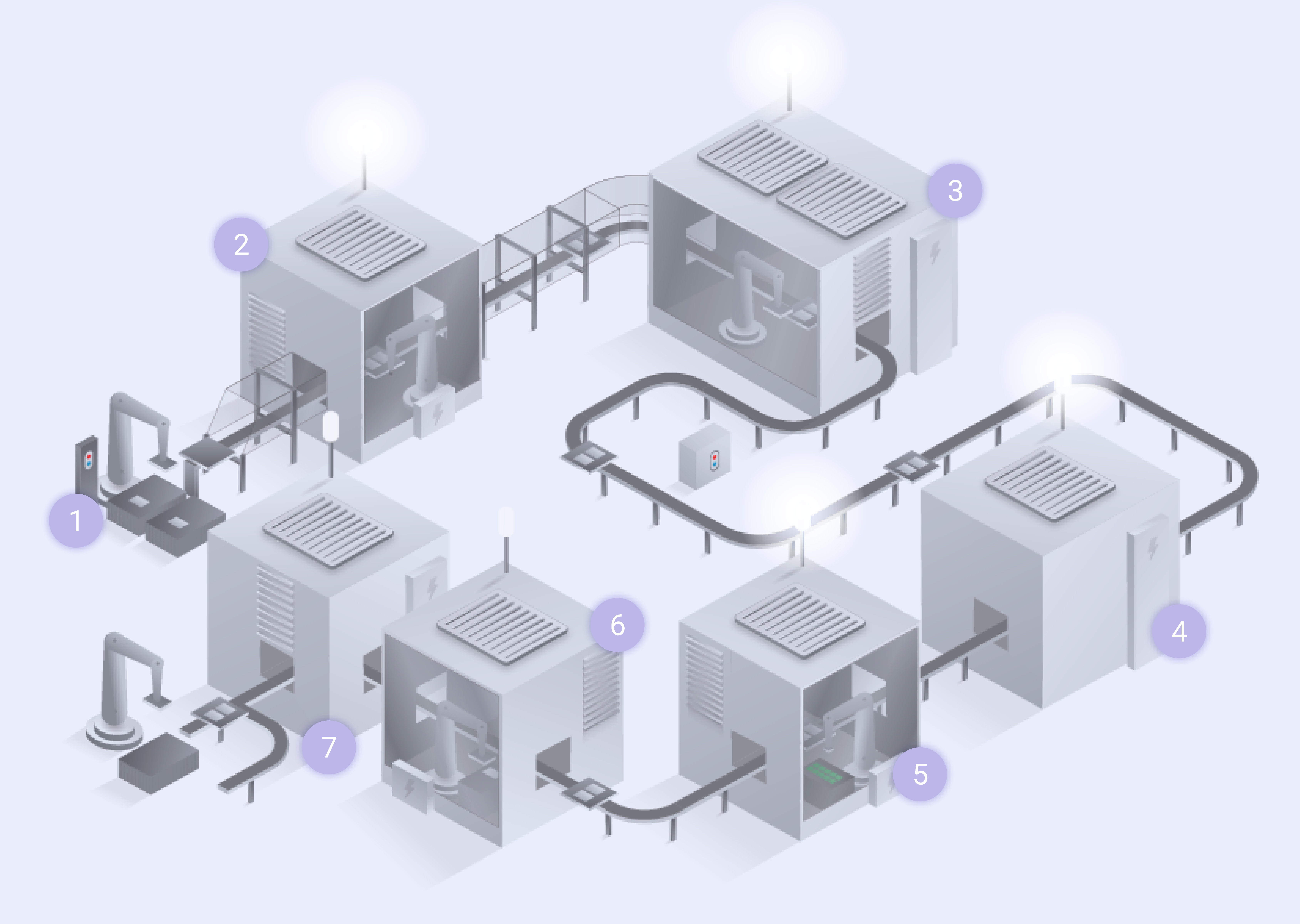

Automatic or semi-automatic assembly line with advanced AI vision system to check component position and measure assembly tolerances for a consistently excellent final product.

We strive to provide a well-rounded experience and stand by your side every step of the way: from concepts to design, through the definition of all display assembly operations, their construction and automation, to deployment and ramp-up production support. We pride ourselves helping our customers reach changing KPIs with continuous improvement throughout the production lifecycle.

Committed to economically sound environmental sustainability, we place great care in the handling of materials, rationalising their packaging, and reducing energy costs. Interoperability in transport with autonomous guided vehicles for automatic line loading and unloading minimises the need for human access. Clean room operation costs are reduced by optimising the footprint of the assembly line or eliminated by emulating a clean room environment inside individual cells.

To make sure that every technical requirement is met, and scrap is kept to a minimum, our in-line quality assurance inspects the input materials as well as product output after every critical operation, so that any defects are detected early and mitigated promptly. With high precision and nest tolerances as low as 5 μm, every part is placed exactly where it belongs. To ensure exact attachment, the system monitors fastening parameters such as torque, rotation, and stroke.

All parameters and measurement values are recorded and reported, along with product identification, to the Manufacturing Execution System (MES). This system utilizes RFID tracking to accurately assess the location of each part within the assembly process. With machine status reports, any anomalies can be immediately recognized and mitigated, enhancing overall process reliability.

No matter the size or shape of the end product, we offer tailored solutions that combine advanced automation, modular design, and stringent quality control. With a focus on operational sustainability, we deliver not just products, but long-term value.

assembly tolerances

first pass yield

particle filtering

technical availability

machine scrap rate

safe speed movement

The assembly chamber is maintained at constant overpressure and the laminar flow above the assembly area is considered. The quantity and size of air particles are monitored in real time and can be reported to the information system if necessary. Every material input includes a pre-cleaning chamber to enable constant production output, assembly component loading, and maintained cleanliness.

Functional tests require power and communication connections, which we can accommodate with a wide variety of connectors, such as flexible PCB, FPC, MQS, or HSD. Wherever possible, we use a floating contact head with mechanical guides to achieve a precise connection. Where that is not feasible, a high-resolution vision system detects the position of the connection pins and the contacting head. It is mounted on high precision servo driven actuators, which can achieve contacting pitch as low as 0,5 mm using contacting probes with a tip diameter of only 0,27 mm.

With the help of advanced vision systems, robots can pick components from a wide range of packaging options such as trays, bins, and rolls. To be able to automatically assemble complex parts, gripper compensation technology is implemented. The camera system can detect the precise part position in the gripper to help the robot compensate for any differences and make sure that every product is assembled correctly.

The use of an advanced vision system enables dynamic component pick by precisely detecting their position. This reduces the packaging and labour costs, as the machines can process unevenly packaged input materials without operator intervention, allowing for long autonomy. A feeding system is chosen depending on the component packaging, which could be a stack feeder, roll feeder, vibrating feeder, or tray feeder, using AGV loading and unloading wherever practical.

inClass assembly lines are engineered for versatility and can accommodate a wide array of LCD shapes and sizes that are suitable for automotive applications. Whether it’s a display for an instrument cluster, infotainment, or any others such as mirror and AC control, they can be assembled on inClass lines.

Additionally, the system is not limited to just LCDs; it can be adapted to work with OLED displays. It is crucial that inClass lines are adaptable to different products on the same line. Changeover to a completely different product can be done by swapping grippers and carriers, or the entire line can be designed to be able changeover by the push of a button.

Quality control in inClass assembly lines is completely adaptable to fulfill both specific customer requests and our own high standards of quality. Each cell has individual quality control mechanisms to make good on every opportunity to catch discrepancies early and reduce scrap, ensuring inClass assembly lines a 99% first pass yield or higher.

DMC or RFID tracking can be incorporated for comprehensive traceability all along the line, as well as seamlessly integrated with MES and ERP for information-based support on a higher level. Additionally, individual inSpect visual quality control cells can be fully integrated for specialized quality checks at the start of line, end of line, or anywhere in between where they are needed.

Yes, the InClass assembly system is modular by design. This is a significant advantage as it allows for easy adaptability and upgrades, making it a future-proof investment. Whether there’s a need to integrate new technologies, adapt to different display sizes and types, or lower cycle time by multiplying bottleneck operations, the modular design ensures that the line can be easily modified to meet these new requirements.

This flexibility is particularly important in the fast-paced automotive industry to match with constant technological advancements, market segmentation and just-in-time manufacturing demands.

Yes, we offer support contracts that can be tailored to meet specific customer requirements – whether it’s regular maintenance, software updates, or emergency support, we offer comprehensive after-sales service. Maintenance intervals are anticipated based on manufacturers’ recommendation for standard components and wear analyses for custom components.

This ensures that the assembly line continues to operate at peak efficiency, reducing downtime and maximizing productivity. We also pride ourselves in continuous knowledge support and the ability to offer extensive trainings before and during production ramp-up; this means savings on labour costs down the line since the operators are empowered to operate the line independently and don’t spend time on avoidable inefficiencies.

Yes, any new line or new functionality can be commissioned fully remotely. We offer 3D remote commissioning with a complete digital twin to fully align expectations and mitigate any shortcomings before the line ever reaches the factory floor. Taking advantage of all remote work tools at our disposal, we work with the customer’s team as if we were physically working together. Virtual commissioning allows for quick changes and iterations to be made in parallel with other project activities, optimising time and resource use and ultimately delivering a more refined product.

inClass assembly systems comply with a set of European and international standards to ensure the highest levels of safety, functionality, and reliability. Specifically, they comply with the following:

SIST EN ISO 12100:2011: An international standard for the safety of machinery, providing guidelines for risk assessment and risk reduction to help designers and manufacturers achieve safety in the design phase.

SIST EN 60204-1:2018: A European standard that deals with the safety of electrical equipment of machines, setting general requirements for the electrical equipment used in machines to ensure both the safety of the operator and the correct functioning of the machine.

2006/42/EC: The Machinery Directive of the European Union, which sets legal requirements for harmonisation of essential health and safety requirements for machinery within the European single market.

2014/35/EU: The Low Voltage Directive, which covers the safety of electrical equipment under 1000 V AC and 1500 V DC for both commercial and household electrical equipment.

2014/30/EU: The Electromagnetic Compatibility Directive, which ensures that electrical and electronic equipment doesn’t generate, or is not affected by, electromagnetic disturbance.

inClass assembly lines are engineered for versatility and can accommodate a wide array of LCD shapes and sizes that are suitable for automotive applications. Whether it’s a display for an instrument cluster, infotainment, or any others such as mirror and AC control, they can be assembled on inClass lines.

Additionally, the system is not limited to just LCDs; it can be adapted to work with OLED displays. It is crucial that inClass lines are adaptable to different products on the same line. Changeover to a completely different product can be done by swapping grippers and carriers, or the entire line can be designed to be able changeover by the push of a button.

Quality control in inClass assembly lines is completely adaptable to fulfill both specific customer requests and our own high standards of quality. Each cell has individual quality control mechanisms to make good on every opportunity to catch discrepancies early and reduce scrap, ensuring inClass assembly lines a 99% first pass yield or higher.

DMC or RFID tracking can be incorporated for comprehensive traceability all along the line, as well as seamlessly integrated with MES and ERP for information-based support on a higher level. Additionally, individual inSpect visual quality control cells can be fully integrated for specialized quality checks at the start of line, end of line, or anywhere in between where they are needed.

Yes, the InClass assembly system is modular by design. This is a significant advantage as it allows for easy adaptability and upgrades, making it a future-proof investment. Whether there’s a need to integrate new technologies, adapt to different display sizes and types, or lower cycle time by multiplying bottleneck operations, the modular design ensures that the line can be easily modified to meet these new requirements.

This flexibility is particularly important in the fast-paced automotive industry to match with constant technological advancements, market segmentation and just-in-time manufacturing demands.

Yes, we offer support contracts that can be tailored to meet specific customer requirements – whether it’s regular maintenance, software updates, or emergency support, we offer comprehensive after-sales service. Maintenance intervals are anticipated based on manufacturers’ recommendation for standard components and wear analyses for custom components.

This ensures that the assembly line continues to operate at peak efficiency, reducing downtime and maximizing productivity. We also pride ourselves in continuous knowledge support and the ability to offer extensive trainings before and during production ramp-up; this means savings on labour costs down the line since the operators are empowered to operate the line independently and don’t spend time on avoidable inefficiencies.

Yes, any new line or new functionality can be commissioned fully remotely. We offer 3D remote commissioning with a complete digital twin to fully align expectations and mitigate any shortcomings before the line ever reaches the factory floor. Taking advantage of all remote work tools at our disposal, we work with the customer’s team as if we were physically working together. Virtual commissioning allows for quick changes and iterations to be made in parallel with other project activities, optimising time and resource use and ultimately delivering a more refined product.

inClass assembly systems comply with a set of European and international standards to ensure the highest levels of safety, functionality, and reliability. Specifically, they comply with the following:

SIST EN ISO 12100:2011: An international standard for the safety of machinery, providing guidelines for risk assessment and risk reduction to help designers and manufacturers achieve safety in the design phase.

SIST EN 60204-1:2018: A European standard that deals with the safety of electrical equipment of machines, setting general requirements for the electrical equipment used in machines to ensure both the safety of the operator and the correct functioning of the machine.

2006/42/EC: The Machinery Directive of the European Union, which sets legal requirements for harmonisation of essential health and safety requirements for machinery within the European single market.

2014/35/EU: The Low Voltage Directive, which covers the safety of electrical equipment under 1000 V AC and 1500 V DC for both commercial and household electrical equipment.

2014/30/EU: The Electromagnetic Compatibility Directive, which ensures that electrical and electronic equipment doesn’t generate, or is not affected by, electromagnetic disturbance.

Reach out for personalized service and expert guidance tailored to your unique needs. Our team is ready and eager to respond to any challenge.